Cruising Sailors Forum Archive

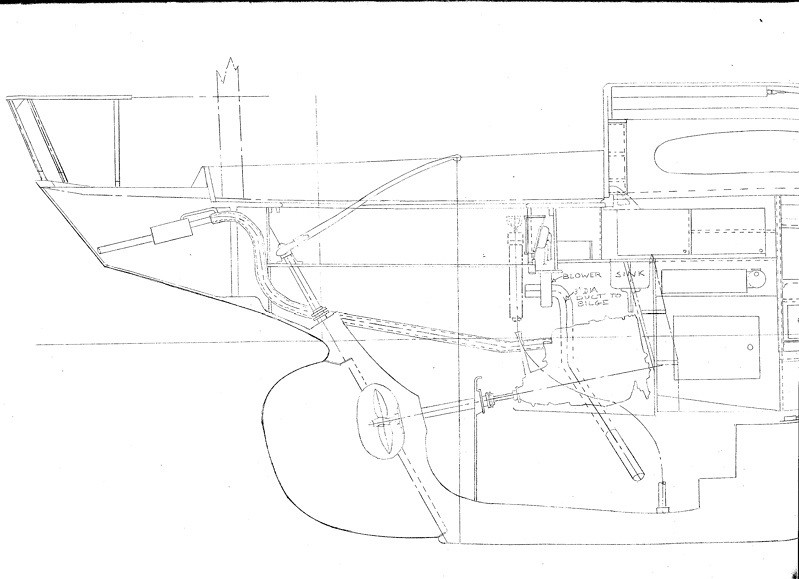

It sure looks like it according to this original Alden drawing. The Graymarine was removed in 1978 and replaced with a Nissan diesel. I've since replaced that with a newer little used Nissan SD 22 4 cylinder diesel. So I just put a new gasket on the exhaust manifold to solid copper(or some mixture of noncorrosive metals) exhaust line.

There is a bellows shaped flexible copper connection between the exhaust manifold and the copper exhaust. The exhaust line consists of the inner copper pipe and an outer jacket pipe of copper. Raw water is injected just after the flexible connection, into the outer jacket. That cools the exhaust pipe as seawater flows toward the stern in the outer jacket. The outer jacket ends, the water flows through a 3/4" pipe, and into the a cast iron marine muffler.

This exhaust can have a catastrophic end (so I'm told, and I believe is true). When the inner pipe fails(presumably 54 years old, when does that happen?), seawater flows into the exhaust pipe. If the engine doesn't start immediately, water backs into the cylinders.

With my cockpit coming out in the spring, I plan to scrap the old exhaust(a little reluctantly as it works so well). I'd like to use a simple Vetus water cooled muffler.

Plan: black iron riser out of the exhaust manifold - as far up as is doable will be well above WL - water injection elbow to rubber exhaust, etc. I think I need to added a siphon break(wasn't needed in the old version) to the raw water line into the injection elbow.

I don't have much room for the muffler. The smaller volume model will be the best fit.

The dangerous crux of this new system (it seems to me) , is that if the engine doesn't start, the waterlock muffler fills - the hose fills - then the engine fills. You live with that achilles heel on any marine exhaust where the engine is below the exhaust outlet. Correct? That's how it was on my last boat and frankly I never thought much about it(that engine took forever to start when cold).

I figure about 5' of 2" hose is needed to get to the high point of the exhaust hose - aft of the cockpit well - then all down hill to my outlet. The outlet height- more than a foot above the WL - is fine(as proven by 54 years).

Any reason this idea wouldn't work? What do you think I'll find when (if) I cut out the double wall copper exhaust line?

Messages In This Thread

- Could I have my original Graymarine engine exhaust -c.1961 - on my boat?