Cruising Sailors Forum Archive

I take my mast down every year and leave it on the boat when I haul out. I've also traveled the Erie and Oswego Canals with a similar system on a 33 foot boat. I'm with Tom, wood is the way to go for this.

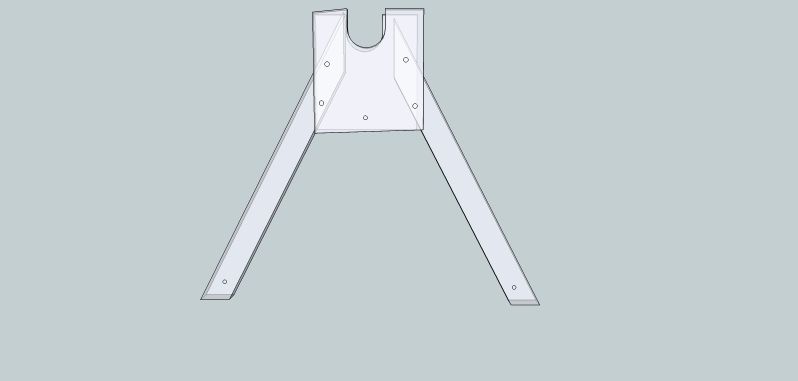

I don't have any pictures at the moment and I'd like to apologize for the crude modeling but I only have Google Sketchup on this PC and I really don't know how to use it. My mast cradles are each a pair of 2 x 4s cut at the bottom to match the deck and cut with vertical edges at the top to clear the mast. These are sandwiched between two plywood side plates with an over sized cutout at the top for the mast. The cutout is over sized to accommodate shag carpet padding to protect the mast. I use two carriage bolts to hold each leg to the plywood. This keeps the assembly secure but also allows you to fold one leg when not in use. The bottom of each leg has shag carpet to protect the deck and toe rail.

I have a hole near the bottom of each leg with a line passed through to tie the strut down. There is also a hole through each side plate with a line which keeps the strut in place while lowering the mast. I strongly suggest using a sturdy line wrapped around the mast and under the side plates then down to a strong attachment on the deck fore and aft of the strut to brace the mast. Do this for both struts while moving the boat. I've done this in steep waves motoring to windward with the water coming over the bow and I was able to get the mast secure enough that it didn't shift (much).

I use two struts, the one on the fore deck spans the entire deck and sits just inside the toe rails. The aft one on my boat sits in the cockpit with the feet just inside the coaming. On longer boats it is common to use a third strut in the middle but I have seen a 2 x 4 (or 4 x 4) stuck through the mast partners on keel stepped masts, this won't work for deck stepped.

I hope this helps.