Cruising Sailors Forum Archive

Re: Interesting inserts. How is that done?

In Response To: Interesting inserts. How is that done?  ()

()

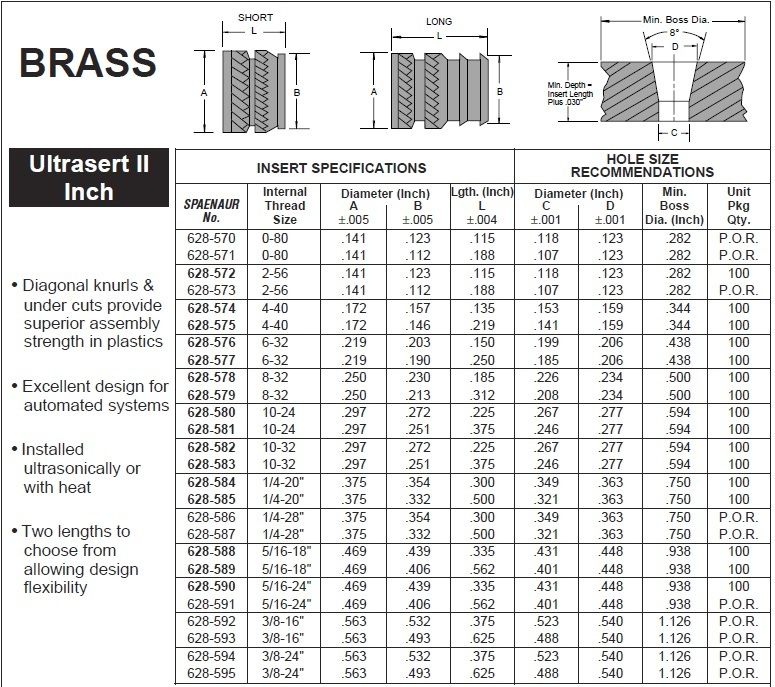

You drill a hole slightly smaller than the OD of the insert, for instance a ¼-20 Ultrasert II is .375"OD, drill a .359" hole. The table below gives recommended dimensions but I have often just ignored the taper and drill somewhere in between the larger and smaller dimensions. Line the tip of the insert up with the hole and slowly push it into the hole with a hot soldering iron while the plastic melts around it. I should qualify my experience by saying I have never used these around salt water. They are "brass" but I don't know what kind of brass.

Messages In This Thread

- starboard related question

- Re: starboard related question

- There are a few products that might work

- Re: starboard related question

- I'd use Heli-Coils

- Look into threaded inserts...

- The reason that I like Heli-coils is they are an expansion fitting that doesn't depend on threading

- My concern with threaded inserts is that in SS they may gall in removing the bolts......

- Look into rivnuts.

- Galling and inserts

- Interesting inserts. How is that done?

- Re: Interesting inserts. How is that done?

- Re: Interesting inserts. How is that done?

- Interesting inserts. How is that done?

- Look into threaded inserts...

- I could be way off here but

- Re: starboard related question