Cruising Sailors Forum Archive

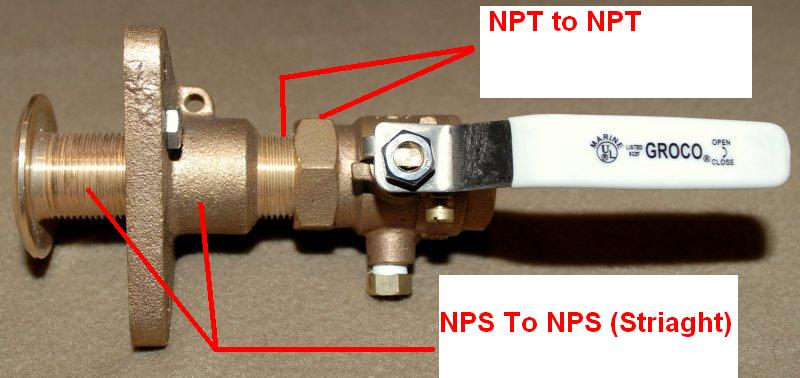

Even if you don't through bolt the flange you would be wise to use a thru-hull threaded into at least a flanged adapter on the inside. If you have wood backing plates that are dry, usually pretty rare, then you could simply screw the flange into the wood to secure it from twisting. This will at least give you the proper thread match between ball valve and the flanged adapter.

I have all but stopped using flanged seacocks in favor of the flanged adapter. After replacing some bound up 2" "proper" seacocks in a customers boat that were only 9 years old I vowed to continue using the flanged adapters. That job took nearly 12 hours of labor because they were through bolted flanges that needed to be dug out faired etc. etc. and the wood backing blocks were punky and also destroyed by the 5200 use by the installing boat yard. Bottom line is with the new fiberglass backers and flanged adapters the next valve failure will take about 1/2 hour, if that, with the toughest part getting the hose off the hose barb.

Messages In This Thread

- Thru Hulls... R&R

- Don't forget to drop the mast before hauling to eliminate undue stress on the rig.

- Let the yard do it

- Gene you've read all the advice

- That sounds reasonable. What's odd to me, is this a quote, a fixed price to do the job?

- It's not very difficult to do yourself but

- Gene... what is the scope?

- Nobody cares about your boat as much as you do

- Coming in a bit late, I would do it myself..

- Gene..

- Gene..

- GeneC where are you located?

- Use Marelon

- Don't forget to drop the mast before hauling to eliminate undue stress on the rig.