Cruising Sailors Forum Archive

Both Marelon and UL Marine rated bronze seacocks are fine. Marelon certainly has the edge in corrosion resistance but the failure rate of them is quite high in my experience. I have personally had four of them with handles that broke off and I know friends and customers who have had similar failures. Marelon has made some changes but I still know of some recent ones that have also experienced the seized ball / broken handle failure and some that were by-pass, sneaking around the ball, leakers.

For me I much prefer a through bolted Groco flanged adapter and then a marine UL rated bronze valve. This allows valve replacement at any time even with the boat in the water and the thru-hull, backing plate and flanged adapter stay sealed to the hull. A little pipe dope on the threads and a new valve threaded on is all it takes for a seacock replacement just about anywhere in the world. Spares can easily be carries on-board. Also with a through bolted flange you will have no worries about it twisting when threading on a new valve.

Proper marine bronze, 85-5-5-5, can last nearly indefinitely IF you don't encounter a hot marina and this is where Marelon shines. This spring I cleaned, lapped and re-built two Spartan Bronze tapered cone seacocks. They were 31 years old and in 100% perfect condition after some cleaning, lapping and greasing. They showed ZERO signs of dezincification or corrosion except for some verdegris ( the harmless green patina). I suspect they could easily last another 30+ years...

This was posted recently on one of the Catalina forums regarding a Marelon valve failure. Pretty scary stuff..

Quote:

Originally Posted by dwarburton:

Last night we were closing up the boat after a week long cruise, and I tried to shut off the galley seacock. We are always diligent about closing the seacocks when we leave the boat. But no good deed goes unpunished.

I turned the handle on the Forespar Marelon seacock and it broke off in my hand. Worse, a solid stream of water began to gush from the hole where the handle fit.

This is not what I would call a "fail safe" design. I immediately pulled out the under sink drawer and put the handle back into the hole. This slowed down the water flow to a trickle, but I could not use the handle to turn the ball to the closed position.

I also couldn't sit there all night like holding the handle, so I asked my wife to get the doomsday box, complete with wooden plugs, a variety of tapes, and my new best friend, silicone Rescue Tape. It is expensive but worth every penny.

Anyway, my wife cut off one foot strips and I wrapped them around the valve, and holding the valve handle in place. The Rescue Tape stuck to itself, even under water. Absolutely amazing stuff. In a few minutes, I had the water flow slowed to a trickle, and I could think about what to do next.

I wish we had caught the whole thing on video. The unedited version of events is much more exciting...

I used to actually rep a couple of valve lines and have been to the plants where they make them. One inherent problem with plastic valves, and not just Marelon/DuPont Zytel/Xytel, but PVC also, is the difficulty in making a perfectly round ball. Many industrial Zytel valves have adjustable seats or use special o-rings in combination with the valve seats to accommodate the inherent difficulty in making perfectly round plastic balls. Add to that the issue that many plastics can swell slightly after they come out of the mold and now add some sea life growth and you can see a decent rate of failure if all the precautions are not taken in the design stage.

I know Forespar has worked very, very hard to reduce these problems and I do believe the new valves are significantly less prone to failure, not heard of many of the "OEM" series failures, but I have just seen to many failures, in total, and worked selling valves for long enough to not go back to Marelon/Zytel at this point. Marelon is NOT ruled out by any means and I do still install them when a customer wants them and knows the history.

The material they are made of, DuPont Zytel, is great stuff, and strong, but the balls need to rotate and some times they just don't do this reliably. The new OEM style valves I believe use o-rings to help the balls with shape issues but o-rings can get chewed up by marine growth on the ball and I know of two OEM valves that would not possitively shut off. The handles turned and the balls moved but the water was still leaking in around the ball or through the valve somehow. While not a lot of water, is they were still a "leakers".

They DO have some solid benefits but I am still not yet personally comfortable with the high rate of failures I've seen, have had personally (4) and read about.

I am NOT, not recommending them, just advising the use of careful research. If one starts to get hard to turn you will want to.....REPLACE IT ASAP....

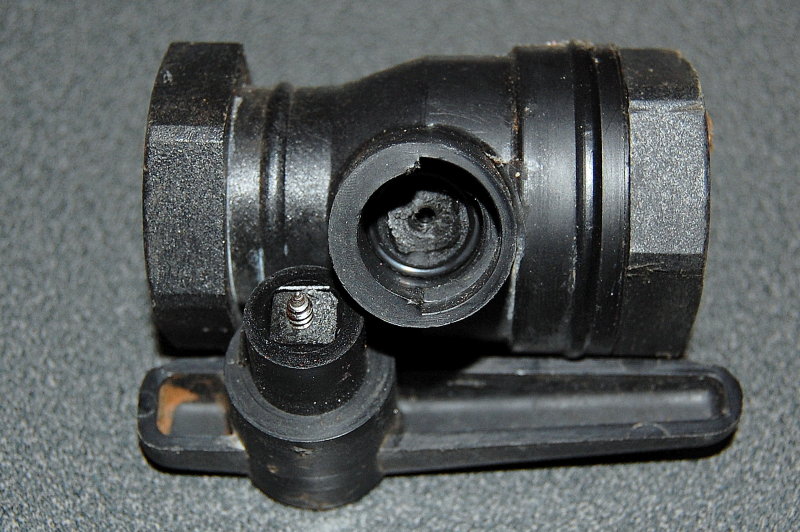

This was one off one of my own boats..

Messages In This Thread

- Thru Hulls... R&R

- Don't forget to drop the mast before hauling to eliminate undue stress on the rig.

- Let the yard do it

- Gene you've read all the advice

- That sounds reasonable. What's odd to me, is this a quote, a fixed price to do the job?

- It's not very difficult to do yourself but

- Gene... what is the scope?

- Nobody cares about your boat as much as you do

- Coming in a bit late, I would do it myself..

- GeneC where are you located?

- Use Marelon

- Don't forget to drop the mast before hauling to eliminate undue stress on the rig.